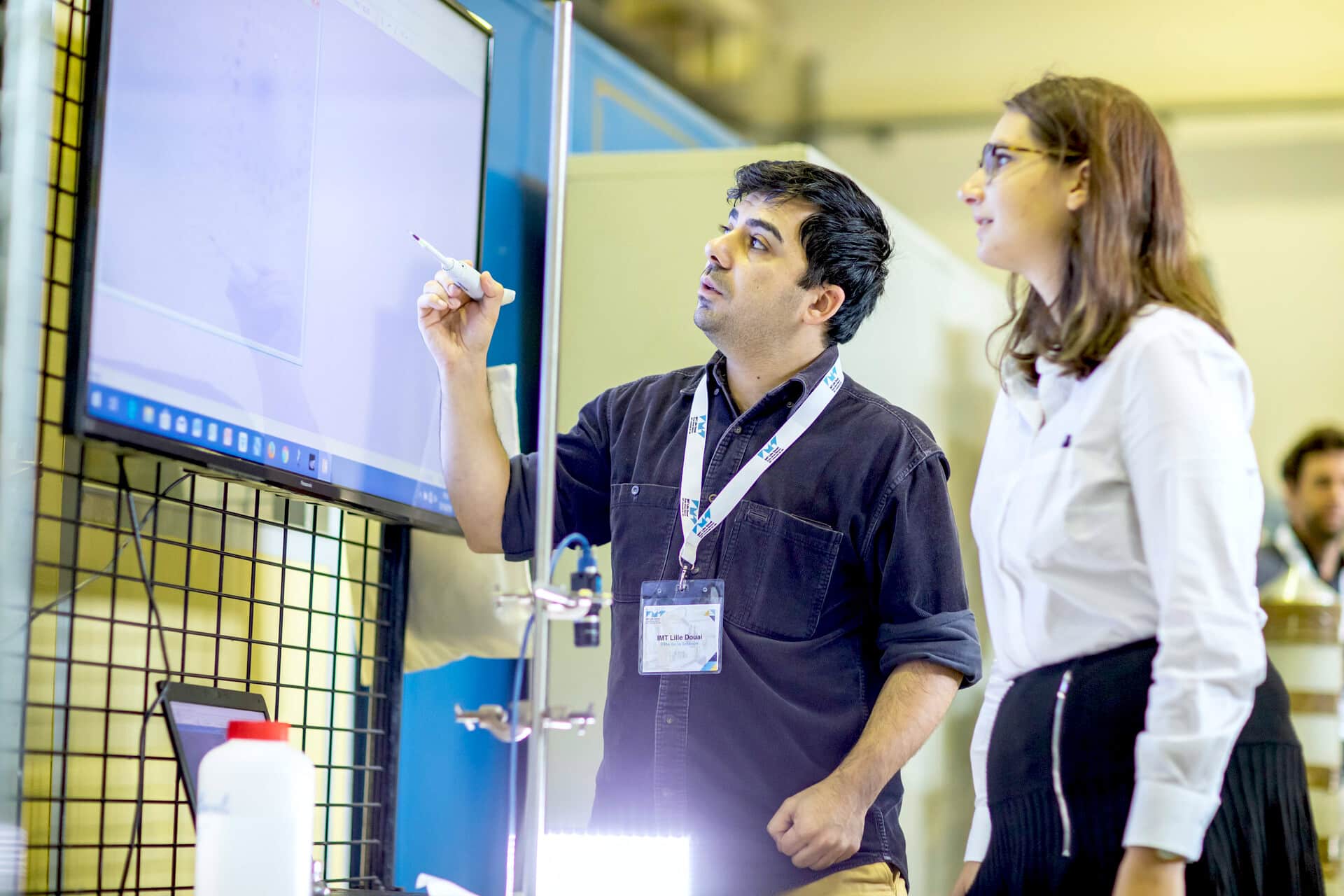

Fluidic Environments and Components Theme – MFC

The key challenges facing the industry of the future include reducing energy consumption, sustainable energy management, durability, reliability, safety, eco-design of components, optimisation of component geometry, and the reduction of load losses and the size of components. These themes provide a perpetual source of scientific and technical issues at the heart of the Fluidic Environments and Components Thematic Group (GT MFC) in relation to changing industrial and societal needs in the fields of energy efficiency and sustainable development.

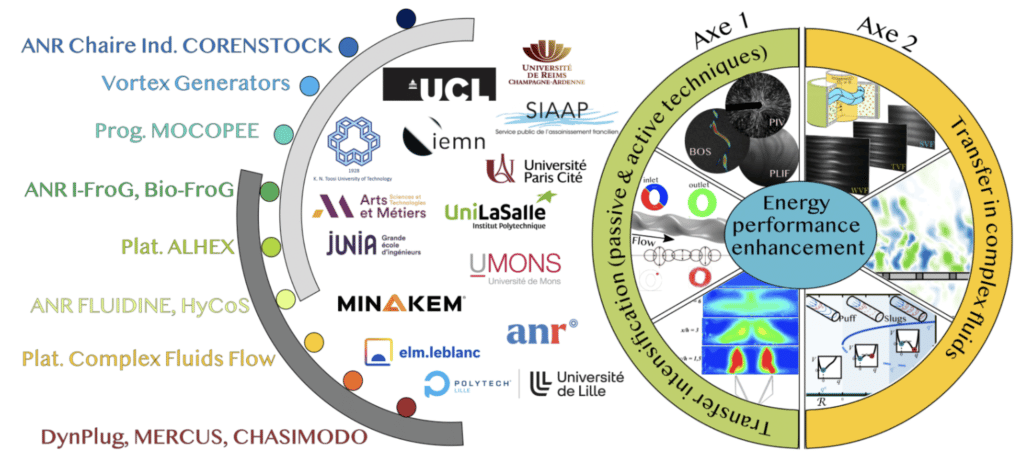

The Fluidic Environments and Components (MFC) Thematic Group brings together the majority of stakeholders involved in experimentation, modelling and digital simulation of flowing fluid environments for the efficiency (including energy efficiency) of thermo-fluidic components and processes. This is directly related to the performance of specific components (exchangers, reactors, storage units, etc.) in which exchanges occur between energy, materials and species involving fluids with complex rheology and/or suspensions. The key to improving the performance of these components is primarily based on exchange intensification techniques, which can be passive and/or active, and whose successful implementation is greatly dependent on the more or less complex rheological behaviour of the fluids (sludge from water treatment plants, slurries, biofluids). In return, it is possible to intensify the exchanges by altering the rheology of these fluids (innovative heat transfer fluids, etc.). The Fluidic Environments and Components group’s scientific and technological objectives are to improve the understanding of fluidic phenomena to ultimately develop more energy efficient and sustainable components. This requires determining which intensification strategies to implement based on the physics of transfer phenomena and the fluids’ rheological properties. In this context, the MFC’s research activities focus on two research areas:

Research Area 1: Intensification by passive and active methods – this area is focused on developing several intensification techniques aimed at reducing the exchange surface, increase the heat exchange coefficient, while limiting load losses. The long-term goal is to reduce the size and/or cost of components by making energy systems more efficient. In this context, vortex generation is an effective technique for intensifying exchanges by optimising thermohydraulic performance. This technique involves creating a passive or active disturbance to destabilise the main flow which then becomes more conducive to mixing and convection properties than in its stable version. On the other hand, generating chaos in laminar regime by applying passive wall deformations can effectively increase thermal-hydraulic performance. Finally, the generation of turbulence at low shear stress via innovative oscillating stirring devices appears to be a promising technique for intensifying mixing in shear-sensitive biofluids.

Research Area 1 Deliverables: Passive intensification of transfers:

S. Hamidouche, J. V. Simo Tala, S. Russeil, Analysis of flow characteristics downstream delta-winglet vortex generator using stereoscopic particle image velocimetry for laminar, transitional, and turbulent channel flow regimes, Phys. Fluids, 32, 054105 (2020).

S. A. Bahrani, N. Périnet, M. Costalonga, L. Royon, P. Brunet, Vortex elongation in outer streaming flows, Exp Fluids, 61 (3), 1-16 (2020).

H. Karkaba, T. Dbouk, C. Habchi, S. Russeil, T. Lemenand, D. Bougeard, Multi objective optimisation of vortex generators for heat transfer enhancement using large design space exploration, Chem. Eng. Process., 154, 107982 (2020).

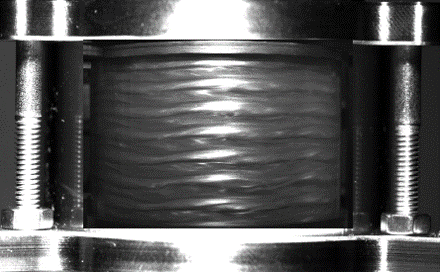

Research Area 2: Complex Fluid Flows – research conducted in this area focuses on hydrodynamics and transfers in complex environments (e.g. non-Newtonian fluids, particle suspensions, biofluids). The need to better understand the mechanisms governing the flow of complex fluids even greater given that these environments are present in numerous industrial applications. The scientific and technological issues are related to the structuring-destructuring of these complex environments when they are subjected to different types of excitations (e.g. hydrodynamic, thermal, mechanical, vibro-acoustic). Interactions between inertia and rheology in the transition to turbulence must be quantified in order to optimise the flow in such environments at an operational level. We seek to control instability and develop flow control techniques.

The activities of these two research areas feature a balance between basic research (TRL 1-3) and application research, with the goal of obtaining a laboratory model or proof of concept (TRL 5-6). This requires the use and development of efficient digital and experimental tools, at various geometric scales, the quantification and analysis of flows in interaction with the rheological behaviour of complex fluids, and the structuring of exchange surfaces and, where appropriate, transfers in solid parts.

Research Area 2 Deliverables: Transfer in complex fluids :

- A. Charles, F. Romano, T. Ribeiro, S. Azimi, V. Rocher, J-C. Baudez, S. A. Bahrani, Laminar-turbulent intermittency in pipe flow for a Herschel-Bulkley fluid: Radial receptivity to finite-amplitude perturbations, Phys. Fluids, DOI: 10.1063/5.0128748 (2022).

- M. Moazzen, T. Lacassagne, V. Thomy, S. A. Bahrani, Torque scaling at primary and secondary bifurcations in a Taylor–Couette flow of suspensions, J. Fluid Mech., 937, A2 (2022).

- T. Lacassagne, T. Boulafentis, N. Cagny, S. Balabani, Modulation of elasto-inertial transitions in Taylor–Couette flow by small particles, J. Fluid Mech., 929, R2 (2021).