LCERI MP’s “EcoMaterials and the Circular Economy” focus area includes two research themes:

- Recycling of polymers, composites and civil engineering materials

- Recovery of waste and bio-based materials

Recycling of polymers, composites and civil engineering materials

With sustainable development in mind, this theme focuses on “materials generated from waste (alternative materials) from civil engineering or polymers and composites with specific use properties” which can offer a new alternative in compliance with the aforementioned requirements. The cornerstone of the scientific reflection is the microstructure which the material must possess in order to obtain the desired use properties (material by design approach). The unique aspect of these themes is its application to a wide variety of multiphase materials, covering the entire range of organo-mineral materials originating from noble or recycled sources. The diversity of cultures both in terms of the nature of the constituents and implementation procedures should allow for scientific openness and a wealth of innovations.

Objectives:

The main objective of the researchers working on this theme is to focus on (design, formulation, mechanical and environmental studies) the following major waste material groups:

Intimate polymer blends (immiscible polymers resulting in separate phases),

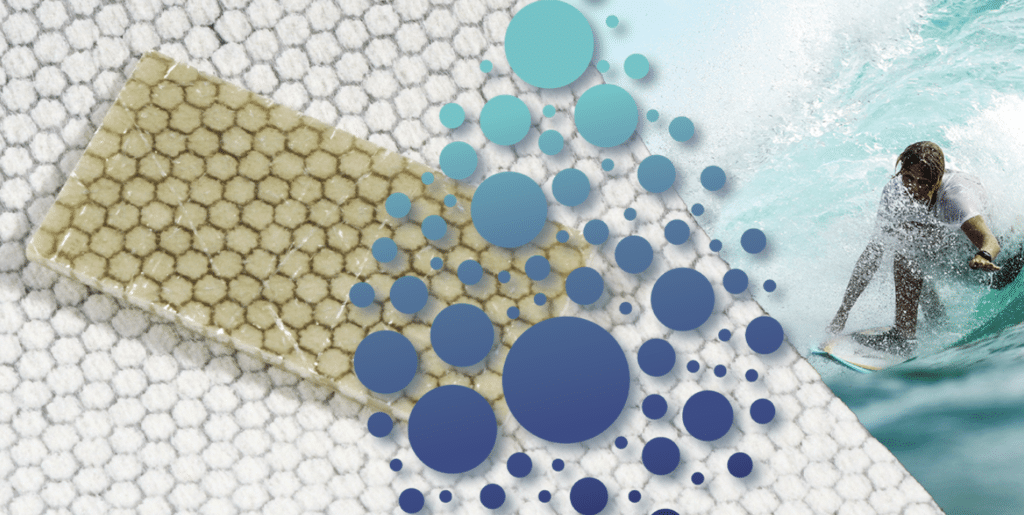

Cellular polymers (open and/or closed-cell polymers),

Functionalised polymers by adding fibre (short, long or continuous) particles (nanometric and micrometric),

Material combinations (multilayer),

Cohesive heterophasic granular materials used in civil engineering (e.g. concrete, reinforced concretes, fibre concretes, mortars),

More or less cohesive heterophasic granular materials used in civil engineering (e.g. soils, road bases).

The research:

For several years, CERI MP has been developing recognised skills in various fields related to the recovery of materials. The following are a few examples of the research:

Incorporation of alternative materials in polymer matrices: one of the lines of research developed at CERI MP is the substitution of waste for certain mineral fillers in the manufacture of composite polymers. This incorporation of waste in polymers and composites requires the control of other parameters during the formulation phase, such as processing temperatures and the workability of the mixtures.

Reintegration of recycled plastics and composites in production units

Improved recyclability of end-of-life plastics and composites

Recovery of plastic/composite materials

Studies on the durability of building materials. To accomplish this, the following procedure is used to conduct a perform study for a given exposure class:

-1. Concrete composition, binder composition and aggregate quality => Upstream optimisation of the composition of concretes and the choice of binders (recomposed binders, eco-binders).

-2. Verification by durability tests on concrete or mortar according to standard NF EN 206/CN (Article 5.3.3) (performance tests and/or durability indicators) and specific tests pertaining to environments not included in this standard => identification of the most relevant tests to be carried out according to the exposure class (sulphate attack, acid attack, microorganism attack, alkali-silica reaction, carbonation, freeze-thaw, porosity accessible to water, porosity to air, etc.)

-3. Microstructural properties (e.g. mineralogy, SEM microindentation) => detailed characterisation of the materials used in the composition of the concretes facilitates their selection to ensure the production of durable materials (internal or external reactions such as secondary ettringite formation).

Research areas:

The three main research areas for this theme focus on studying the following:

On the one hand, new ways of designing existing materials using recycled civil engineering materials, composites and polymers and, on the other hand, how to maximise the desired properties in an effective manner in terms of the cost, quantity of materials, and energy used to produce and apply them;

The potential to reuse end-of-life materials in different forms and for different applications to create new materials;

The possibilities of adapting and, if necessary, modifying conventional plastics processing methods and equipment by adapting the rules for designing parts, tools and machines to enable the use of plastics or other materials from waste or end-of-life products.

Given the complexity and cross-disciplinary skills involved in these fields, the team’s main objective is to understand the complex couplings governing the interactions between materials and their environment by taking an experimental multi-scale approach supported by digital simulations. The key to the team’s operations is to divide this theme into several sub-themes to facilitate the team’s overall direction, promote interactions between researchers to highlight cross-disciplinary skills, and create autonomy and operational flexibility within each industrial project.

Recovery of waste and bio-based materials

The global consumption of materials used in the fields of construction has been growing very rapidly in the past several years. The exploration and mining of current and future deposits is increasingly regulated and difficult to access for economic, societal and environmental reasons. Due to the rising emphasis on environmental preservation, the management and recovery of waste from industrial by- and co-products remain key financial and environmental challenges which are central to sustainable development policies.

Mastering the geotechnical, mechanical, environmental and sustainability constraints of these new materials in the current economic and social context is no longer sufficient when it comes to developing sustainable value chains and viable circular economy loops. The consideration of complex and multi-objective couplings and interactions related to these constraints is a real necessity. In addition, the new French environmental regulations (RE 2020) for new buildings encourage the use of construction methods that emit few greenhouse gases, or even enable the temporary storage of carbon dioxide, as is the case in bio-based materials.

Objectives:

The main objective is to design high-performance materials and eco-materials (bio-based or otherwise). Only a highly multidisciplinary team can achieve this. Given the vast nature of this field, the team has focused on certain subjects based on a dual approach: that of continuity in terms of certain themes in which the team has earned its stripes, such as waste recovery aspects and, secondly, emerging issues through the study of interactions between conventional or bio-based building materials and microorganisms.

The main work includes:

- Design and construction of sediment-based materials. In terms of the work and outcomes of the sediment recovery projects, the teams have made significant scientific advances, in particular regarding the impact of heterogeneities on the laws of the mechanical behaviour of sediments and on the influence of processing methods on the behaviour of sediment-based materials by conducting laboratory tests and instrumented pilot tests (sediment-based road) which are monitored for several years. These studies were conducted through numerous contracts involving sediment managers (e.g. GPMD, MEL, VNF) and industrial partners (e.g. Colas, Italcementi, Lhoist, Baudelet, Envisan) with the end goal of creating value chains. One of the developmental projects for this theme was the creation of the EcoSed Industrial Chair. Digital 4.0 see website : https://ecoseddigital.wp.imt.fr

- Incorporation of recycled or bio-based fibres into cementitious or polymer matrices. Reinforcing matrices with plant or mineral-based fibres from waste represents a real challenge. Processing these fibres is often crucial in order to improve their adhesion and reinforcement properties. Various processing methods are therefore being developed.

- Manufacture of hydraulic/alkali-activated/geopolymer binders. Some industrial waste, by-products and co-products may have high recovery potential, often after activation, as binders or mineral additions. The research teams have therefore been able to develop new hydraulic, alkali-activated and geopolymer-based binders. This development often involves the implementation of new manufacturing processes such as flash calcination or the control of complex chemical balances in the case of alkaline activation and geo-polymerisation.

- Recovery of demolition aggregates produced locally in northern France and Belgium, as part of the Interreg Valdem project

Research areas:

The research strategy for this theme is based on the circular economy principle to develop sustainable materials while protecting the environment and biodiversity.

Two research areas:

The first involves replacing fossil materials with bio-based or partially bio-based products made from waste or co-products. These materials may be thermoplastic polymers (starch, PLA-based) or thermosetting polymers (precursors from vegetable oils) used alone or in mixtures, fillers (nanofillers) and/or reinforcements (natural fibres). They must then be mixed, modified, formulated and processed, in particular by reactive processes (reactive extrusion or rotational moulding, in-situ polymerisation), mechanical (drawing) and physical (irradiation) treatments, addition of bio-based additives (plasticiser, blowing agents) to remedy their lack of properties compared to their fossil-derived counterparts, strengthen the interfaces, facilitate their implementation, and enable specific functionalities. In addition, based on a detailed analysis of the processing-structure-property relationships(instantaneous and long-term mechanical, functional), the processing conditions and design procedures for products and tools should be adapted to suit this particular class of materials (sensitivity to thermomechanical degradation, specific heterogeneity and anisotropy caused by processing). The objective is to maintain performance and functionalities which are at least equivalent to those of the polymers or composites they replaced by adapting, and if necessary, modifying, conventional processes and equipment used for plastics processing by adapting the design rules for the parts, tools and machines.

The second is the replacement of conventional aggregates (fillers, sands, gravel) in the formulation of building materials with products derived from waste or co-products. This field of research combines both knowledge on the control of granular arrangements and compacities and on the performance assessment of these new materials after replacement while also verifying the environmental impact and sustainability of this replacement with regard to current standards.