Advanced Materials and Processes

Materials & Processes

PROJECTS

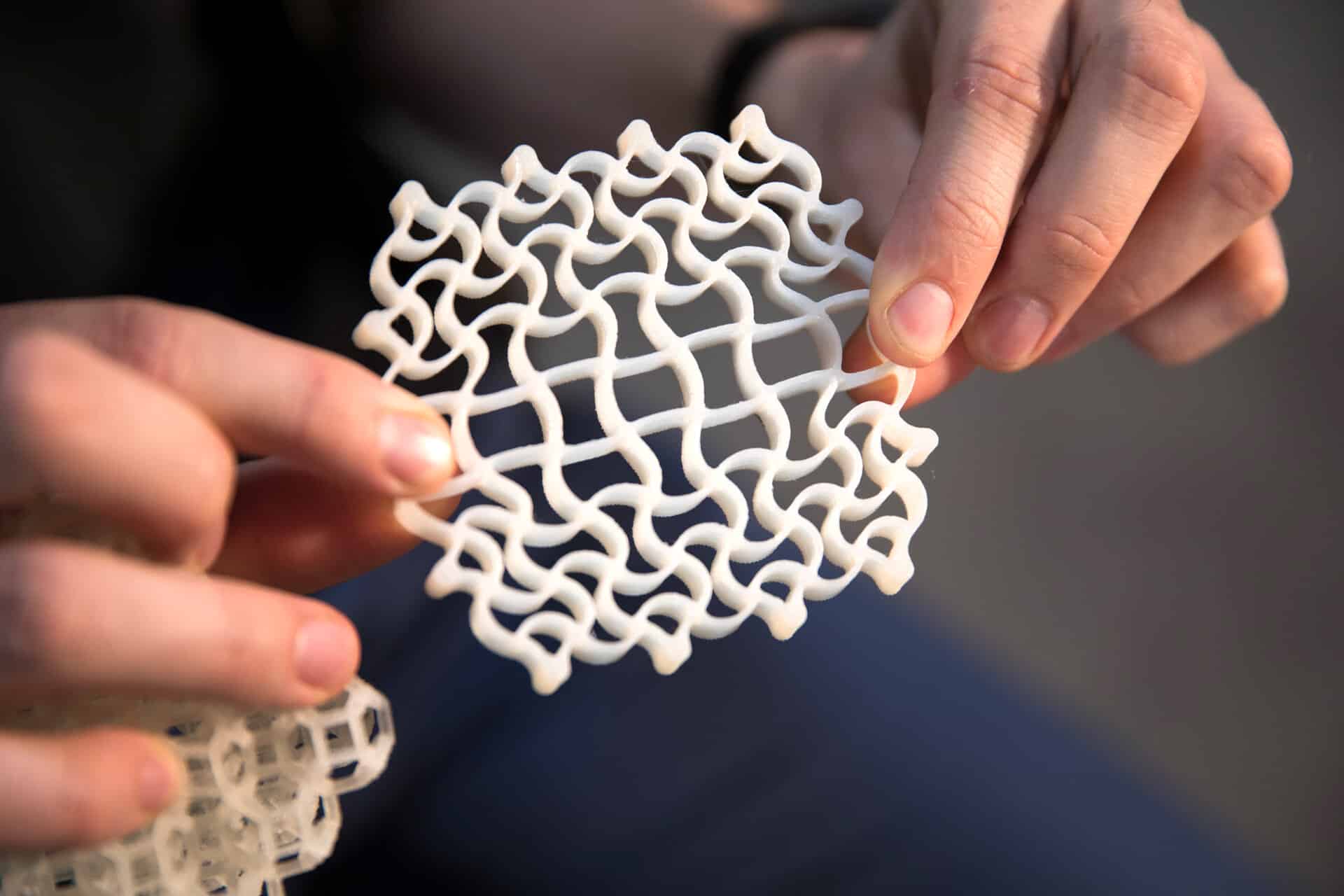

CIRMAP project

CIRMAP project

The CIRMAP project (CIrcular economy via customisable furniture with Recycled MAterials for public Places) is an Interreg North West Europe project with a budget of €7 million running from 2020 to 2023. The objective of this project is to print…

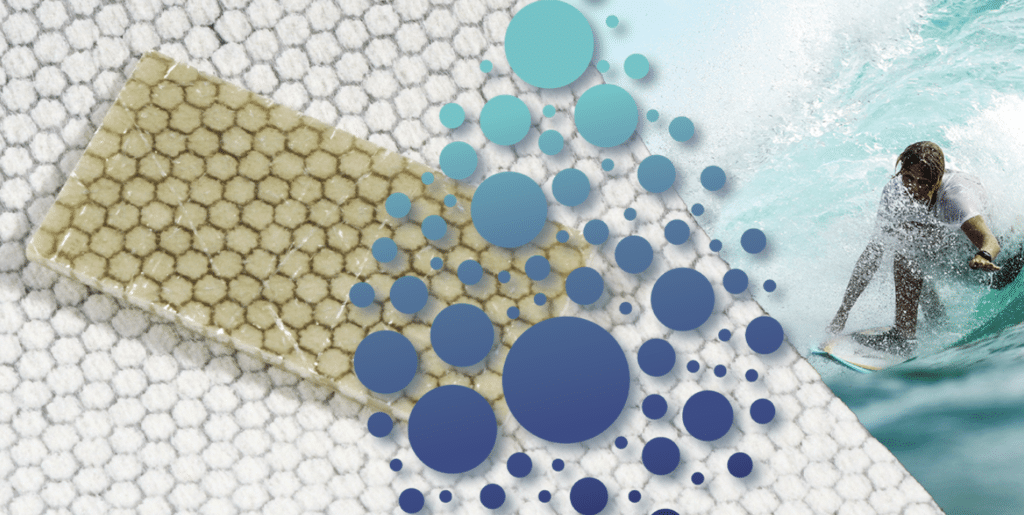

SEABIOCOMP project

SEABIOCOMP project

The SEABIOCOMP project aims to develop new 100% bio-based composite materials in order to reduce carbon footprints, particularly for industrial applications in marine environments. For this project we have developed bio-based polymer non-woven preforms (e.g., PLA) and flax fibres, ready…

BBOBB

BBOBB

The BBOBB project – Building Based on Biobased This project aims to develop a new business model by enabling a change of scale by using of bio-based materials in construction and roads.A number of pioneers in the field of construction…

Want to learn more about

"Advanced Materials and Processes" ?

Our teams at the IMT Nord Europe research centres are here to help

CONTACT US