The test benches are divided into two categories:

ALPHA class equipment:

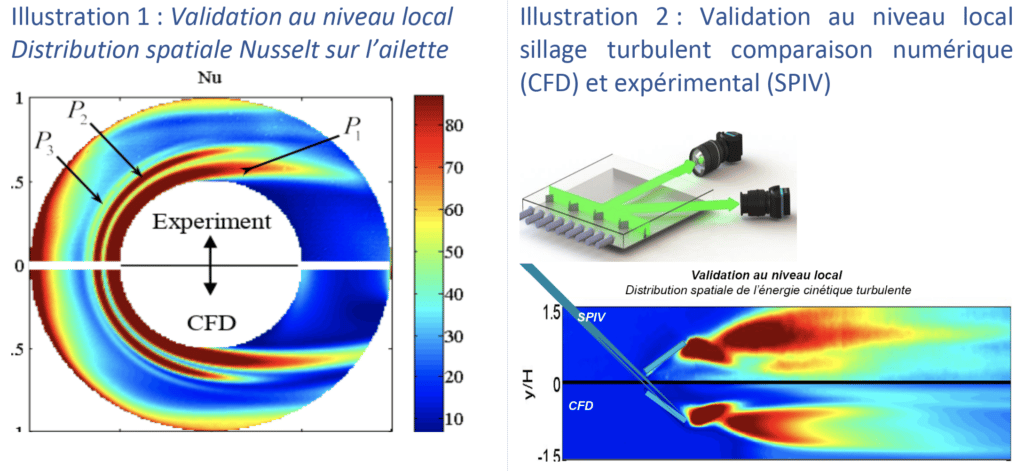

ALPHA class equipment is used to conduct analysis on models built in the laboratory (TRL 2-4). They use measurement techniques to determine local performance using original field identification techniques.

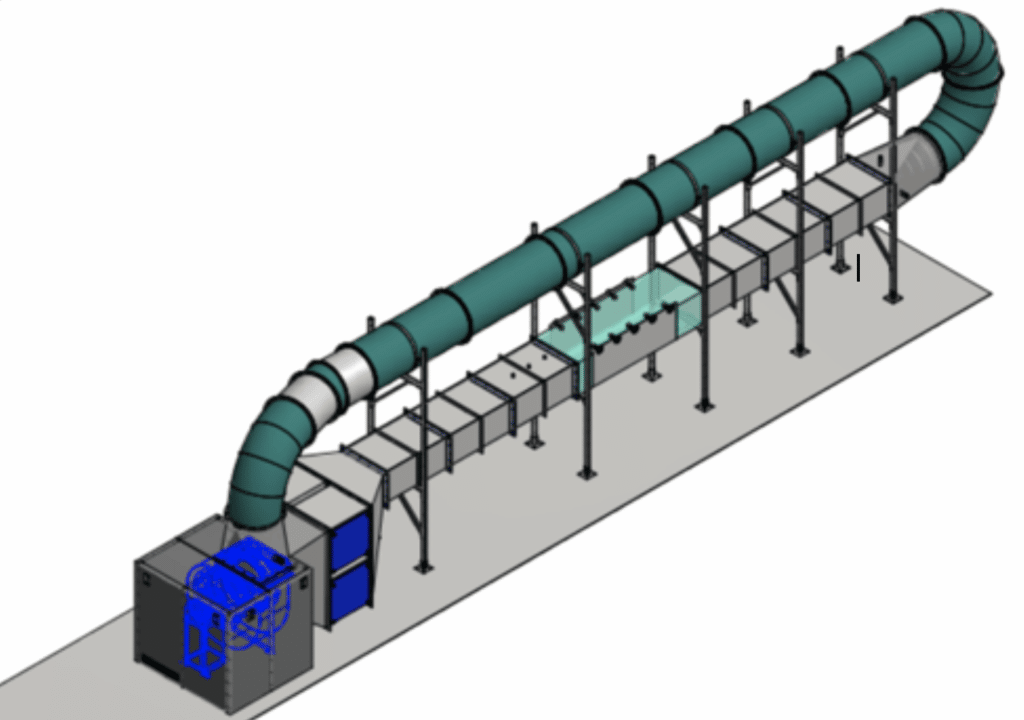

– PGA LOOP (Particle GAs LOOP) wind tunnel: characterisation of deposition and fouling phenomena in heat exchangers based on experiment results from flow bearing particles. Characterisation of the influence of flow on the sensitivity of embedded particle sensors. Return flow wind tunnel with a length of 13 m. Wind tunnel section 650*400 mm2 xxxxx enabling local flow measurements via optical metrology (LDA 2D, SPIV), flow velocity 7-18 m/s.

– Infrared Millimeter Analysis (AMIR: Analyse Millimétrique InfraRouge); characterisation of local convective heat performance. Unsteady wind tunnel; test section approx. 30*200 mm², speed 0-6 m/s; air-conditioned inlet; transparent infrared window (2-16 µm); fast Flir titanium infrared camera: 100 Hz full frame 320*256 pixels, up to 300 Hz windowed – high thermal resolution (NETD 30 MK); FlirA 655 SC high spatial resolution infrared camera: 640*480 pixels; 3 microscope objectives: 100, 50 and 25 µm/pixel. Differential blackbody calibration.

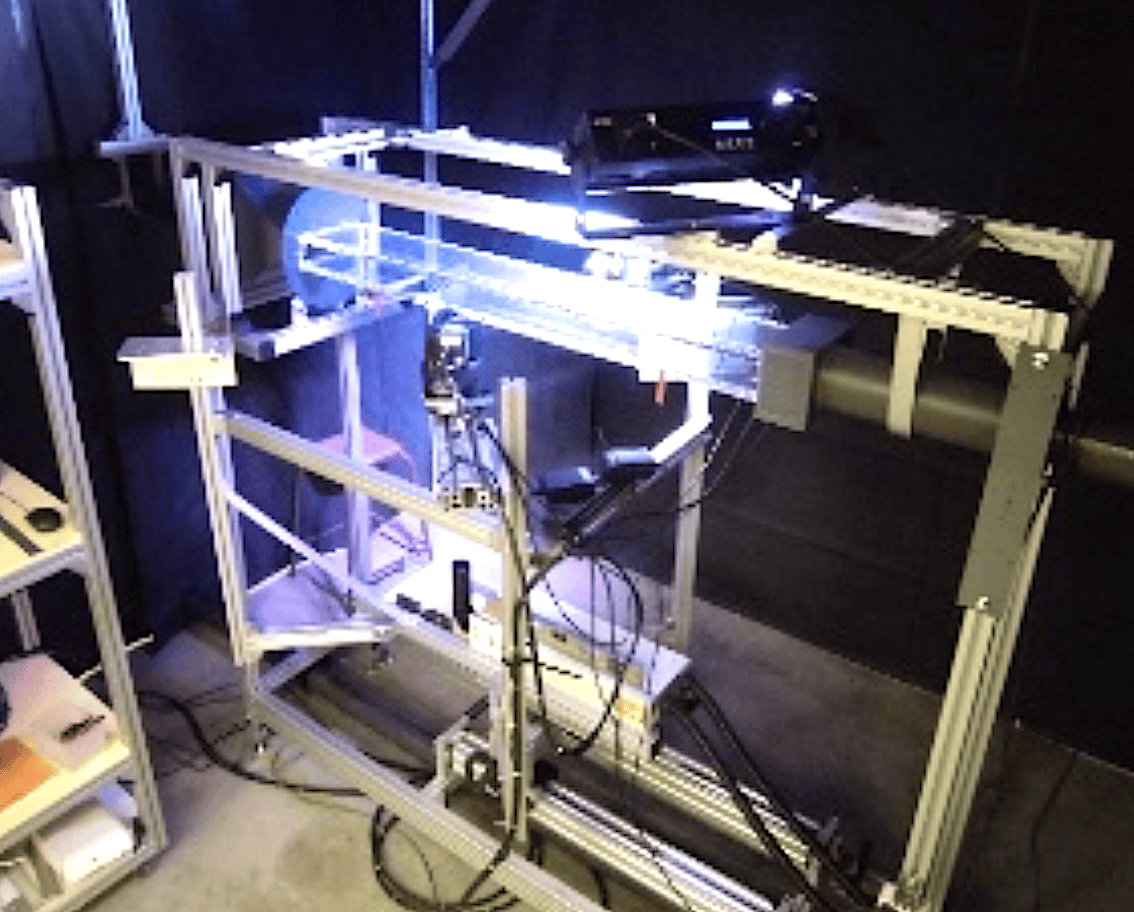

– Local Analysis of Wind Phenomena (ALPHA – Analyse Locale de PHénomènes Aérauliques): Characterisation of wind wakes. Wind tunnel section 50*175 mm², speed up to 7 m/s; camera positioning and translation system. High frequency PIV (2D3C) stereo system (pulsed laser 2x50mJ at 100 Hz; 2 cameras CX 12 M – 160 resolution 4096*3072; 2 cameras SpeedSense ML410 resolution 2560*1600 pixels, 400Hz, memory 12GB; 2 cameras FlowSense EO 16M pix 5Hz).

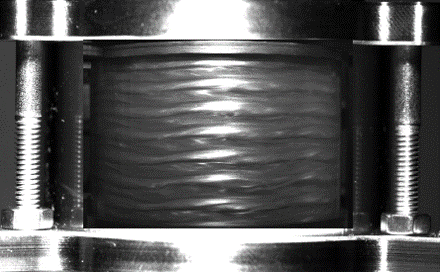

– CHASIMODO (CHAotic SImulation MOdelisation DefOrmation). Chaotic flow characterisation test wind tunnel. Residence time distribution by conductivimetry. Variable flow rates to explore laminar, transitional and turbulent regimes. Associated pressure drops for multiple configurations.

BETA class equipment:

Test benches of representative prototypes (TRL 5-6) manufactured using the manufacturing methods of industrial partners or laboratory prototyping methods. In this equipment, control, monitoring and acquisitions are conducted via a PC and data acquisition and processing software (LabVIEW)

– Fin-side intensification (INCA – INtensification Côté Ailette); testing of miniprototypes of gas/liquid exchangers equipped with high performance surface extensions (fins). Experimental scale: test section measuring 240×200 mm², air speed of 1 to 5 m/s, heat exchanger power 12kW.

– Liquid-liquid heat exchanger analysis (ATEL – Analyse Thermique Echangeur Liquide/liquide): tests of liquid/liquid exchanger prototypes. Determination of performance on both fluid sides. Experimental scale: flow velocity from 0 to 6 m/s, heat exchanger power 80 kW – 140 kW.

– Enhanced Heatsink Analysis Bench (BADIN – Banc Analyse Dissipateur INtensifiés); printed circuit board heatsink tests. Flow velocity from 0 to 10 m/s, heat exchanger power 80-250 W.

The digital component consists of commercial codes and open source multiphysics (e.g. StarCCM+, In Compact 3D, Comsol, Ansys Fluent) using a high-performance computing cluster (CHAPO 1000-core cluster 80 nodes, 20 Tflops). These resources make it possible to carry out high-fidelity digital simulations of flows and transfers while also optimising shapes to propose new types of high-performance thermal components