Equipment

Find out more about our Research Centres facilities

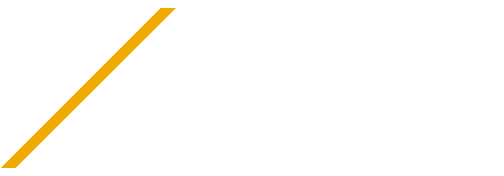

Multi-axial fatigue

Multi-axial fatigue

Multi-axial fatigue Modular test bench for complex loading in tension, bending or compression (static or fatigue), equipped with 4 pistons with capacity of 50 kN/piston, frequency of up to 100 Hz and maximum pitch of 200 mm, which can be…

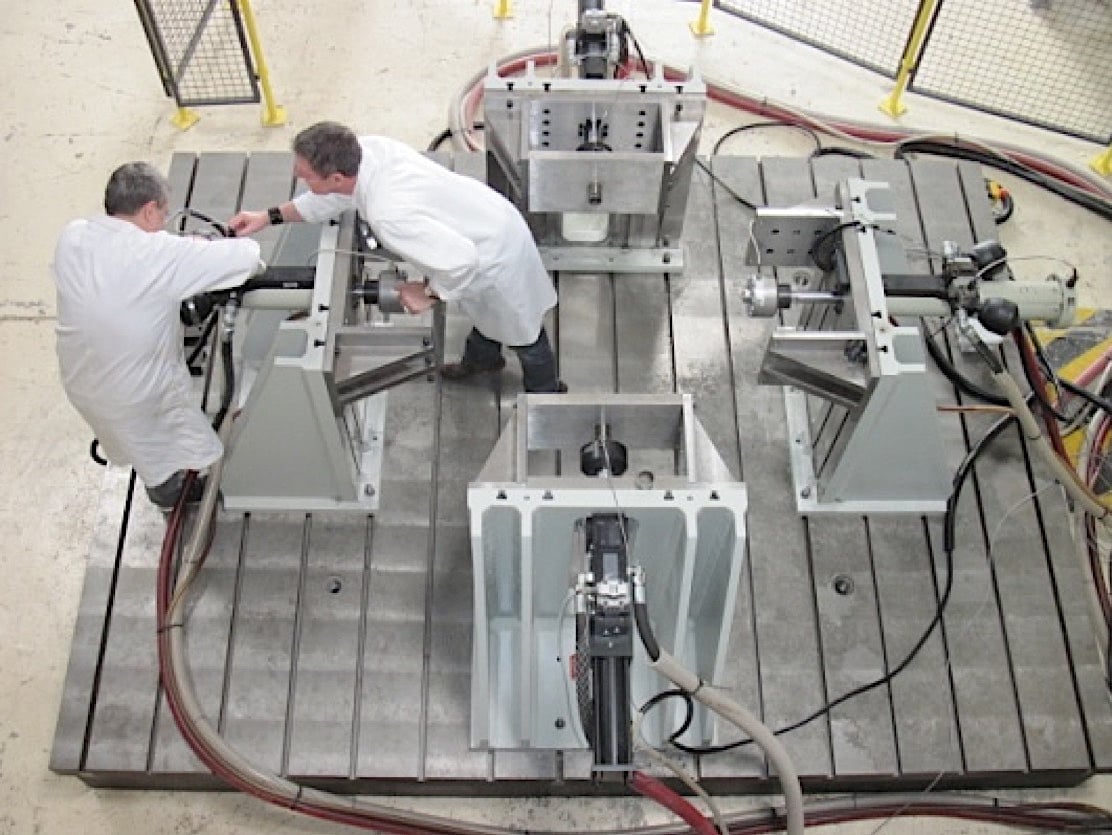

High hydraulic pressure test benches

High hydraulic pressure test benches

High hydraulic pressure test benches Test benches of hollow structures (pipes, reservoirs, pressure vessels), under internal hydraulic pressure up to burst (increasing internal pressure up to 3000 bar), cyclic or constant (fatigue / creep, up to 1100 bar), mono- or…

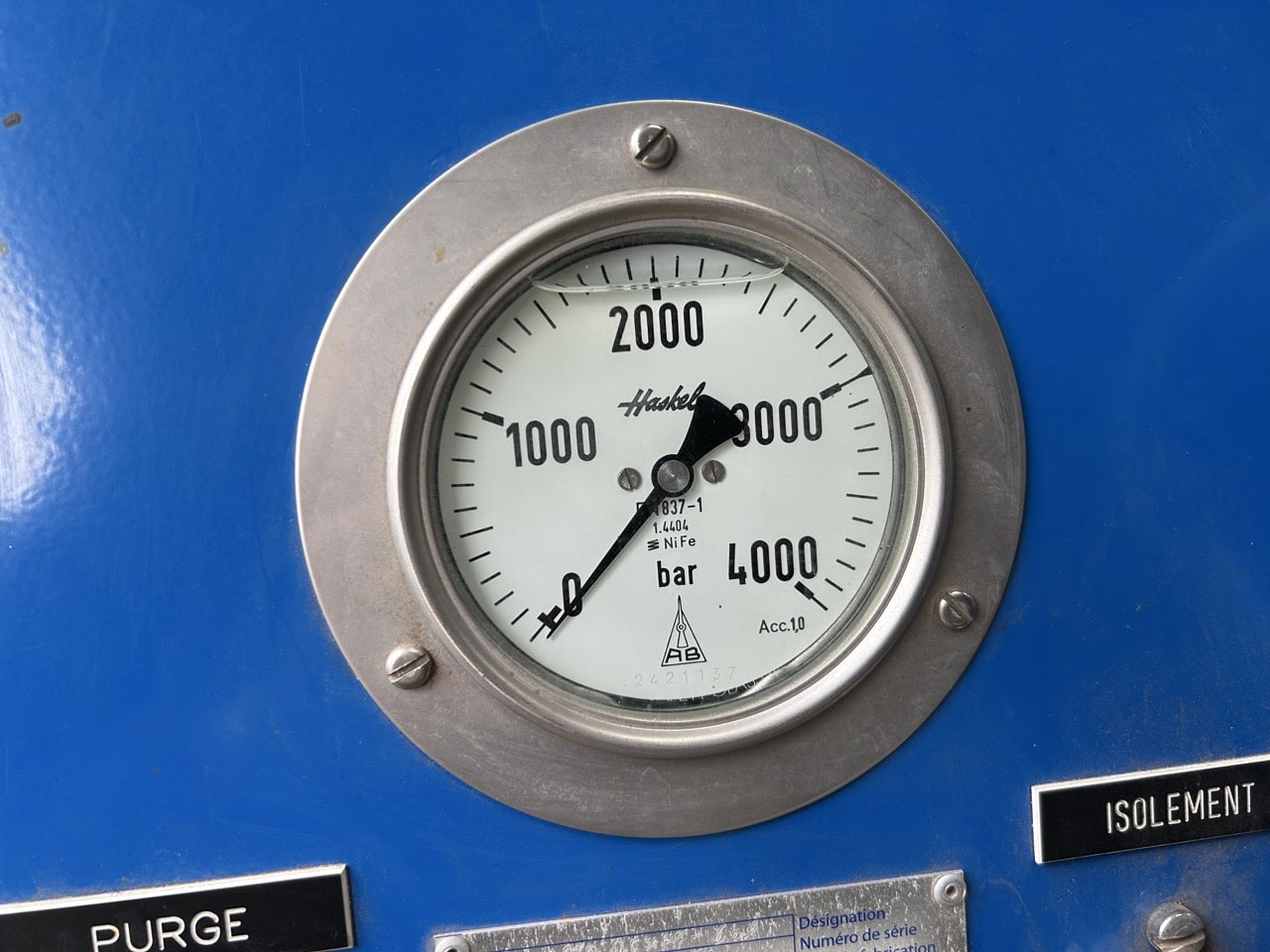

Ultrasonic NDT

Ultrasonic NDT

Ultrasonic NDT Non-destructive ultrasonic testing system (C-Scan tank) using immersion or water jet for large (up to 1500×1000 mm) flat or curved parts (e.g. tubes and tanks) made of polymeric, composite or metallic materials (or hybrids thereof): 3 axes XYZ…

ATS Laboratory

ATS Laboratory

Thermal Analysis & Spectrometry Laboratory The laboratory is equipped with various types of equipment to identify and characterise organic and inorganic materials such as the following: Thermo-Gravimetric Analysis (TGA) coupled with a Fourier Transform Infra-Red spectrometer (FTIR) Differential Scanning Calorimetry…

Granular Simulation Laboratory

Granular Simulation Laboratory

Granular Simulation Laboratory The Granular Simulation Laboratory develops digital and experimental approaches to modelling granular processes. Digital simulation tools (Discrete Element Modelling – DEM – and Smoothed Particle Hydrodynamics – SPH) via High Performance Computing (HPC) are used to simulate…

Filament winding

Filament winding

Filament winding machine Filament winding machine for manufacturing composite tubes and tanks. Possibility of using dry roving and dipping in an impregnation bath, commingled roving with thermoplastic filaments or pre-impregnated tapes. The maximum winding dimension is 1m with a diameter…

Autoclave

Autoclave

Autoclave equipment Autoclave for processing composite materials. Equipped with a 700 x 1300 mm tray, capable of reaching 30 bar at 400 °C with step control for manufacturing cycles.

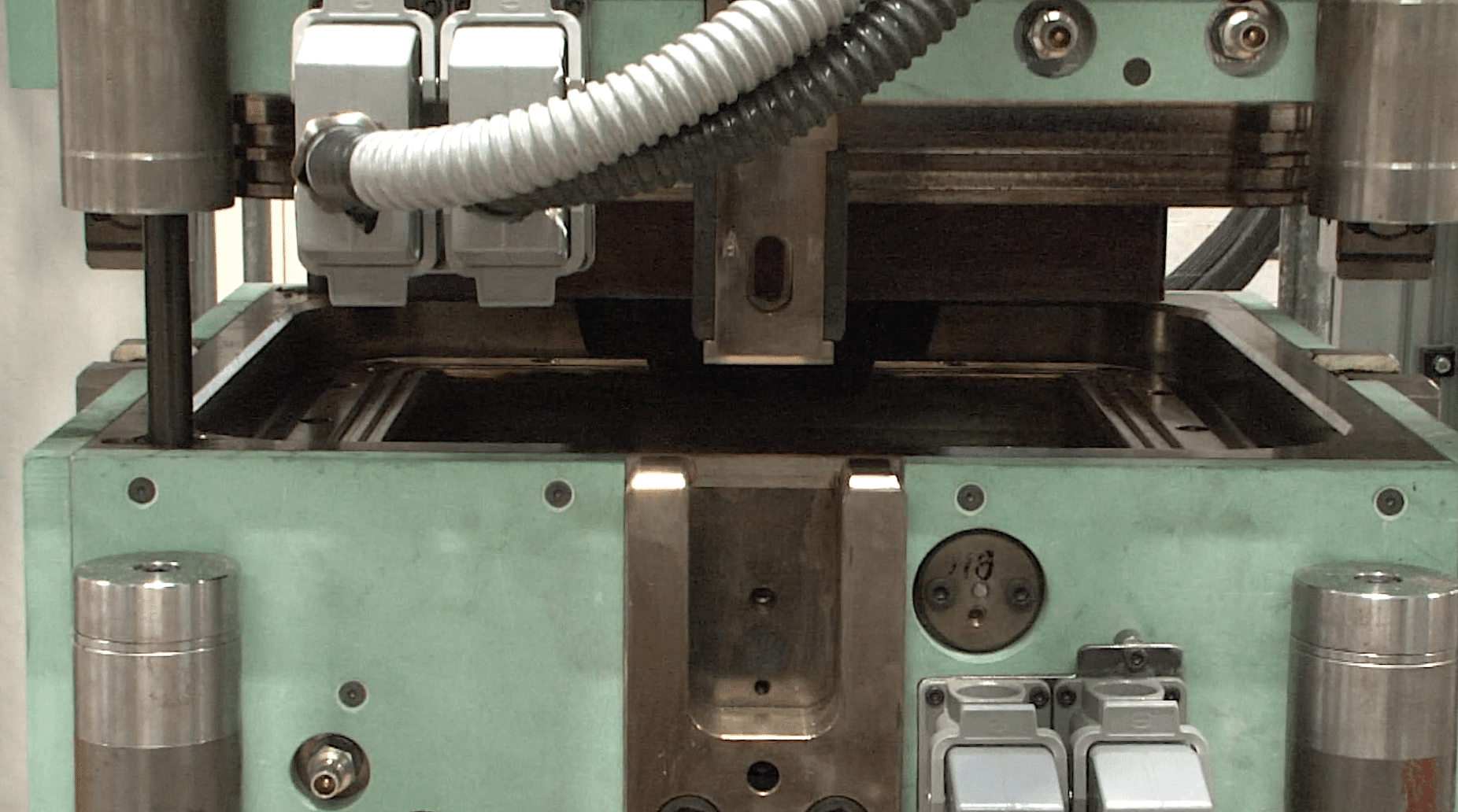

Thermocompression

Thermocompression

Thermocompression press Surface thermocompression press with 600x600mm platens, combined with 4-cavity (450 x 450 mm) tools.The maximum closing force is 1200 kN and maximum temperature is 450°C and it features precise control of the forces applied and the position of…

Want to learn more about

"Équipements" ?

Our teams at the IMT Nord Europe research centres are here to help

CONTACT US