IAM-Lab (Innovative Air Monitoring Laboratory) Joint Laboratory

Energy Environment

Related themes

PROJECTS

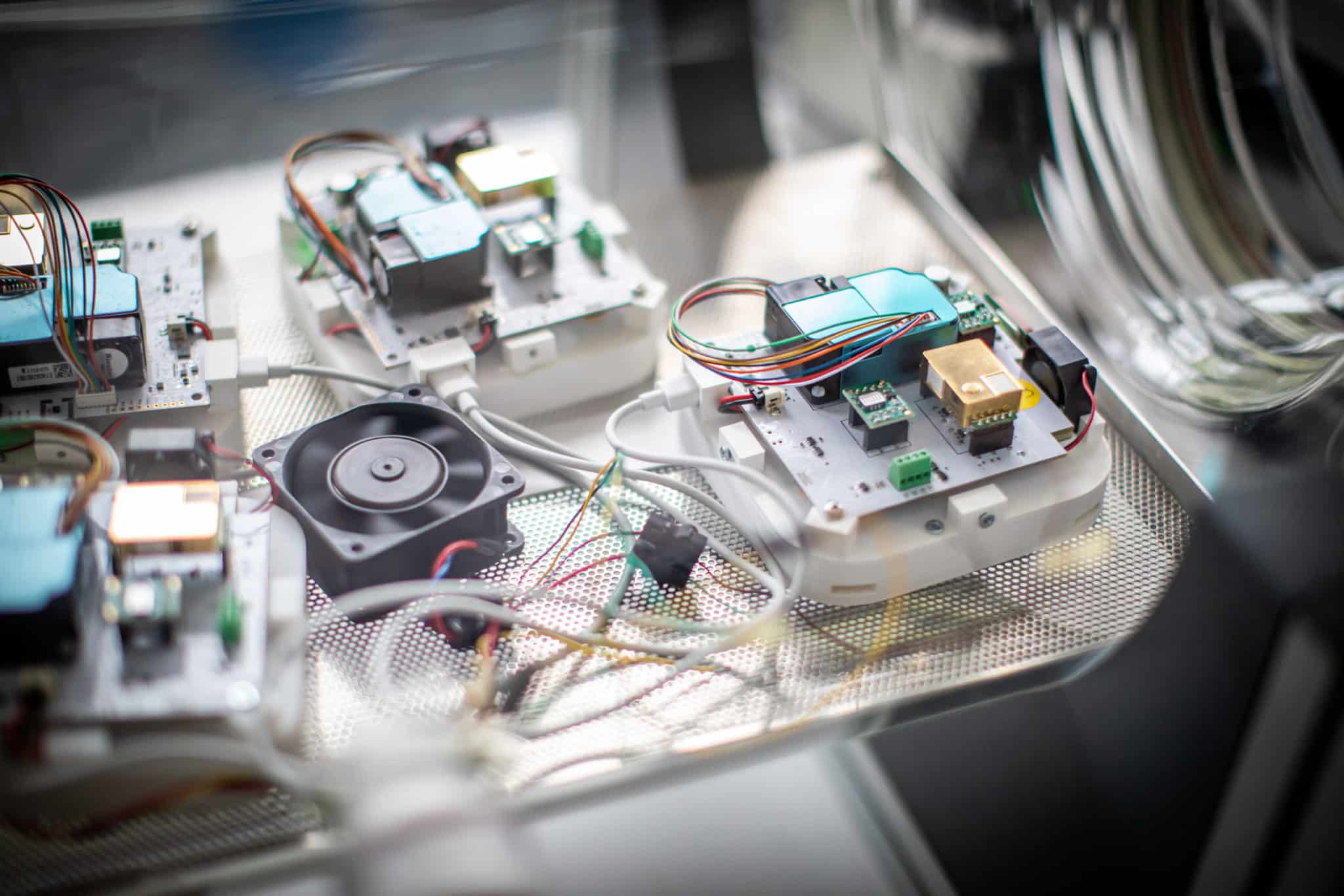

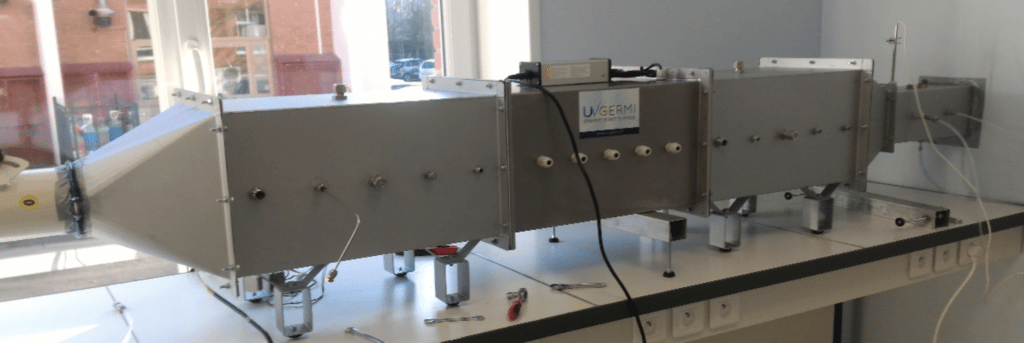

AIRCLEAN

AIRCLEAN

AIRCLEAN project (development of cabin air quality equipment for all aircraft segments) The French AIRCLEAN project was selected as part of the Single Inter-Ministerial Fund’s 22nd call for projects (FUI-22) with the goal of treating aircraft cabin air to ensure…

AMUSENS

AMUSENS

AMUSENS – Transforming the invisible! The idea: developing a multi-pixel gas sensor platform adjustable to a range of gas environments for a wide range of devices and consumer markets Reference Number: 101130159Program type: Horizon EuropeProgram acronym: HORIZON-CL4-2023-RESILIENCE-01-TWO-STAGE The project Gas…

Want to learn more about

"IAM-Lab (Innovative Air Monitoring Laboratory) Joint Laboratory" ?

Our teams at the IMT Nord Europe research centres are here to help

CONTACT US