PACMAQ platform

Digital Systems

Want to learn more about

"PACMAQ platform" ?

Our teams at the IMT Nord Europe research centres are here to help

CONTACT US

Digital Systems

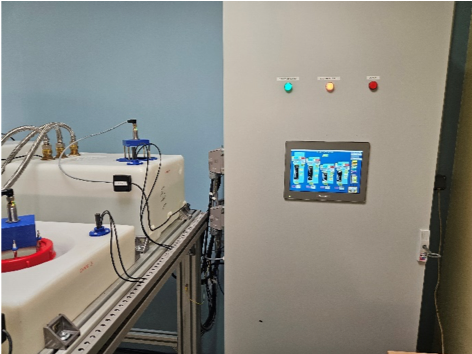

The PACMAQ instrumentalization platform is a functional demonstrator designed as part of the CORENSTOCK industrial chair, jointly coordinated with business EML Leblanc and IMT Nord Europe research centers.

This interdisciplinary platform (including physics and data processing reliant on algorithmic optimization) provides equipment that can be used for teaching, research and scientific popularization purposes.

The PACMAQ platform has extensive monitoring equipment to ensure the smooth progress of our research and teaching activities, which cover several subject areas.

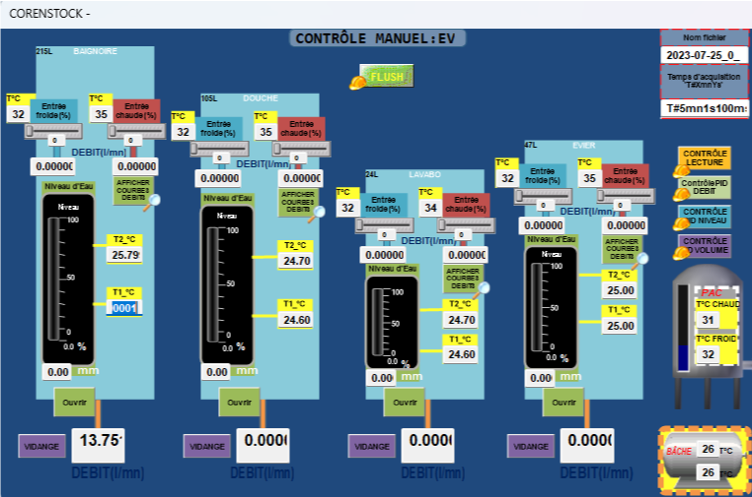

The model can be broken down into 4 main zones:

This set facilitates the manual or automatic reproduction of sanitary hot water uses in a 4-person home and the domestic use of a thermodynamic tank to produce it. To do so, it has 4 tanks: 215 L for a bathtub, 105 L for a shower, 47 L for a sink, and 24 L for a wash basin.

Each of the 4 tanks is equipped with the same monitoring system as detailed below.

Energy study

Monitoring

Security

The PACMAQ platform serves as a demonstrator for domestic use on a 1:1 scale, with the goal of achieving optimization based on behaviors. This demonstrator can be used for teaching, research and scientific popularization purposes.

The equipment described above enables us to define a certain number of functions and use scenarios. A touch-screen Human-Machine Interface was specially implemented to facilitate control and automation of tests using different modes that can be mixed at leisure:

In addition, there are a number of functions developed to facilitate the work of users:

Our teams at the IMT Nord Europe research centres are here to help

CONTACT US